MEA Road Trip: Kilby Farms, LLC in Cecil County

The Maryland Energy Administration (MEA) visited Kilby Farms. LLC to learn more about their daily operations and how they are incorporating sustainability practices into their business. The extended Kilby Farm crew has been in the dairy business for over 100 years. Locally, they began selling ice cream in 2005 and bottling their own milk in 2010, plus they offer home delivery.

Left: Bill Kilby talks about the current generators onsite that the farm will soon replace. Right: MEA’s Brandon Bowser stands in what will be the new location for the farms energy generation. The main generation unit will be delivered to the farm at the end of the year.

Kilby Farms received a $115,500 dollar grant from MEA to install a new, energy efficient, 240 kW biogas fueled Combined Heat and Power (CHP) system. Click here to watch CHP Program Manager, Brandon Bowser explain why this system is unique.

A CHP uses the heat engine to generate electricity and useful heat at the same time. Most CHP systems are run off of natural gas but Kilby will produce all the biogas required onsite to run their system. Kilby has invested heavily in a large-scale anaerobic digester to process the biogas. Click here to learn more about how CHP technology helps to improve energy efficiency or here to apply for a CHP grant, next application deadline is February 12. 2020.

The Kilby digester is fed from a mix of cattle manure and food waste from a local school. The heat recovered by the CHP will be used to condition the digester for optimum biogas production. The farm will generate more power it needs so it will sell some of the energy it produces back to the utility for use. This system upgrade reduces the operating costs for the farm and allows more money be put back into the business.

Bill Kilby in the tasting room where they have chocolate, strawberry and regular milk, eggnog and now a small sampling of craft beers. Ice cream is also available at two full-time retail outlets.

The farm has both Holstein and Jersey cows. Holstein cows are known to produce higher volumes of milk but Jersey cows produce a dense milk with a different level of fat which adds flavor.

Stage one of biogas production is where the manure is moved down past all of cows. The farm’s work to recycle the waste is helping to keep the air, soil and water clean.

The manure is dried out over days, some is used for fertilizer and the rest is used to help produce biofuel which will be used to power the farm’s CHP system. Animal waste to energy is usually not the first renewable energy source that people think of but it is a huge resource for the agriculture industry.

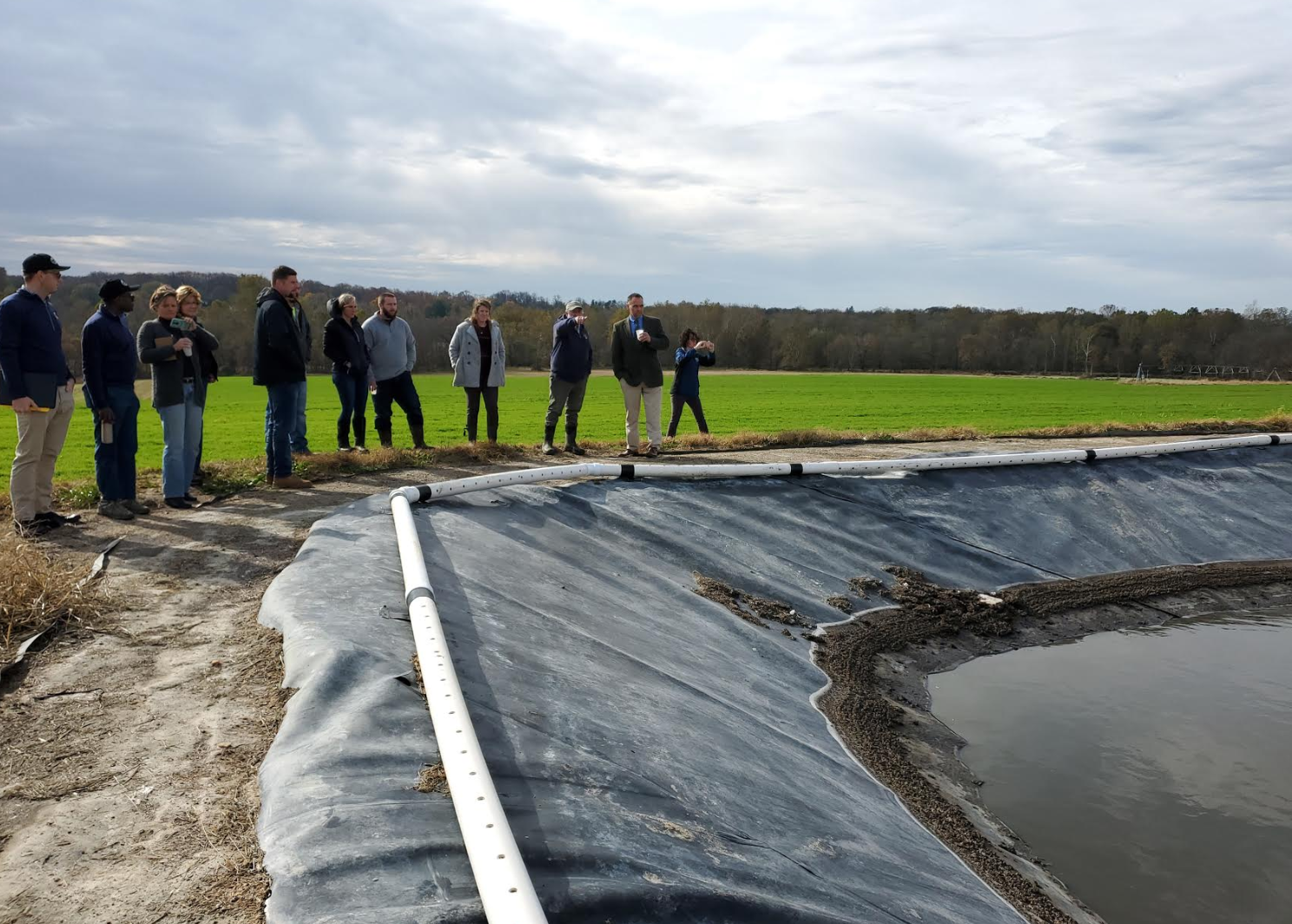

Kilby Farms has two large pools which help them manage a large capacity anaerobic digester.

The concrete tanks safety hold the organic material away from the soil and water table for processing. The anaerobic digestor works very much like a stomach and the balance of materials is critical. Sensors alert Kilby staff if the mix in the digester is not accurate.

1-888-373-7888

1-888-373-7888 233733

233733