Hamilton Associates Realizes Net Energy Reduction Despite Adding Second Shift

From left to right: Rich Sheats, Hamilton Associates; Garry Aime, Maryland Energy Administration; Douglas Hamilton III, Hamilton Associates; Jim Baker, Hamilton Associates; Jack Stephan, Hamilton Associates; Christopher Rice, Maryland Energy Administration; Brandon Bowser, Maryland Energy Administration

By Brandon Bowser, Commercial & Industrial Program Manager

Hamilton Associates, the corporate and administrative driver of the Elevator Safety Company (ELSCO), Air Techniques International (ATI), and Dirt Killer Pressure Washers, has achieved an immense reduction in the energy consumption of its Owings Mills facility through the implementation of a comprehensive energy efficiency upgrade project. Financed in part by a 2016 Maryland Energy Administration (MEA) Commercial & Industrial Grant, the project has resulted in energy reductions so dramatic that savings are still being realized after the addition of a second shift to its operations.

The facility houses the administrative offices and manufacturing facilities for ELSCO, ATI, and Killer Pressure Washers, as well as additional offices on the second floor which Hamilton leases to other entities. The Maryland Regional Manufacturing Institute worked with Hamilton through MEA’s Next Generation Energy Efficiency Gains Program in 2015 to identify opportunities to increase reduce and optimize its energy use, which translated to reduced operating costs. Such improvements were needed by the company to support competitiveness and sustainability so that they could remain committed to growing local employment while maintaining corporate responsibility. Hamilton also wanted to take the improvement project a step further by increasing the efficiency of the office spaces it leases to other businesses on the second floor.

These goals were achieved by the design and implementation of a comprehensive, “deep retrofit” project which improved the consumption of the building’s largest draws on electricity – lighting, HVAC, its air compressor, and its water loop system. It also implemented a new Building Management System to further optimize the energy usage. Specific measures included:

- Upgraded fluorescent lighting to LED with occupancy sensors and daylight harvesting

- Replaced water loop system with a more efficient system that includes variable frequency drives and efficient pumps

- Upgraded 112.5 ton HVAC system on the first floor to increase the Energy Efficiency Ratio (“EER”) from 8.5 to 14.1

- Upgraded the 64.5 ton HVAC system which serves the second floor leased office spaces to increase EER from 8.0 to 13.4

- Repaired leaks to the facility’s compressed air system

- Implemented a new Building Management System

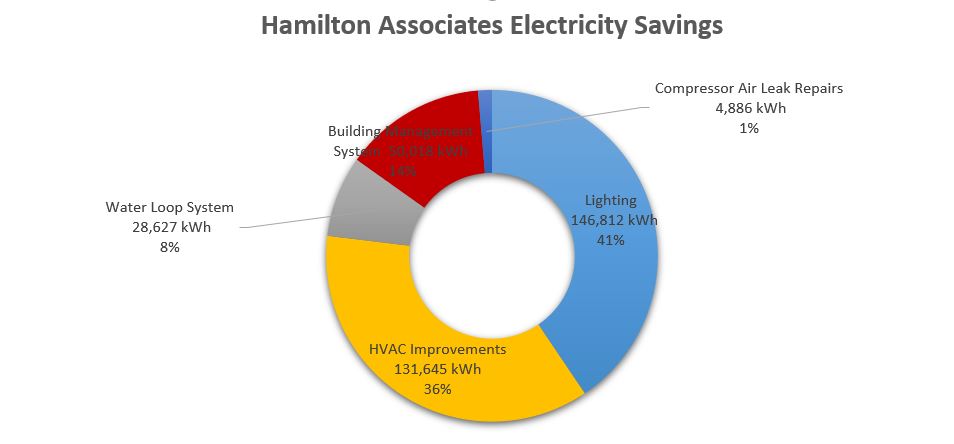

The entire project resulted in over 390,000 kWh of annual electricity savings, which equates to over $51,000 in annual energy costs avoided. The chart below provides more information on the savings achieved by each energy conservation measure (“ECM”).

Hamilton also recently underwent upgrades to its manufacturing equipment and processes which required the implementation of a second shift. Normally, this would result in a sizable increase to electricity consumption. However, the energy efficiency upgrades have instead resulted in electricity consumption costs for its operations on the first floor remaining at 10% below the baseline established before second shift implementation. Additionally, the tenant businesses on the second floor report up to 40% electricity cost savings from their baseline consumptions.

This project is an excellent example of how making investments in the energy efficiency of existing facilities can yield savings that will add to a company’s bottom line for years to come.

1-888-373-7888

1-888-373-7888 233733

233733